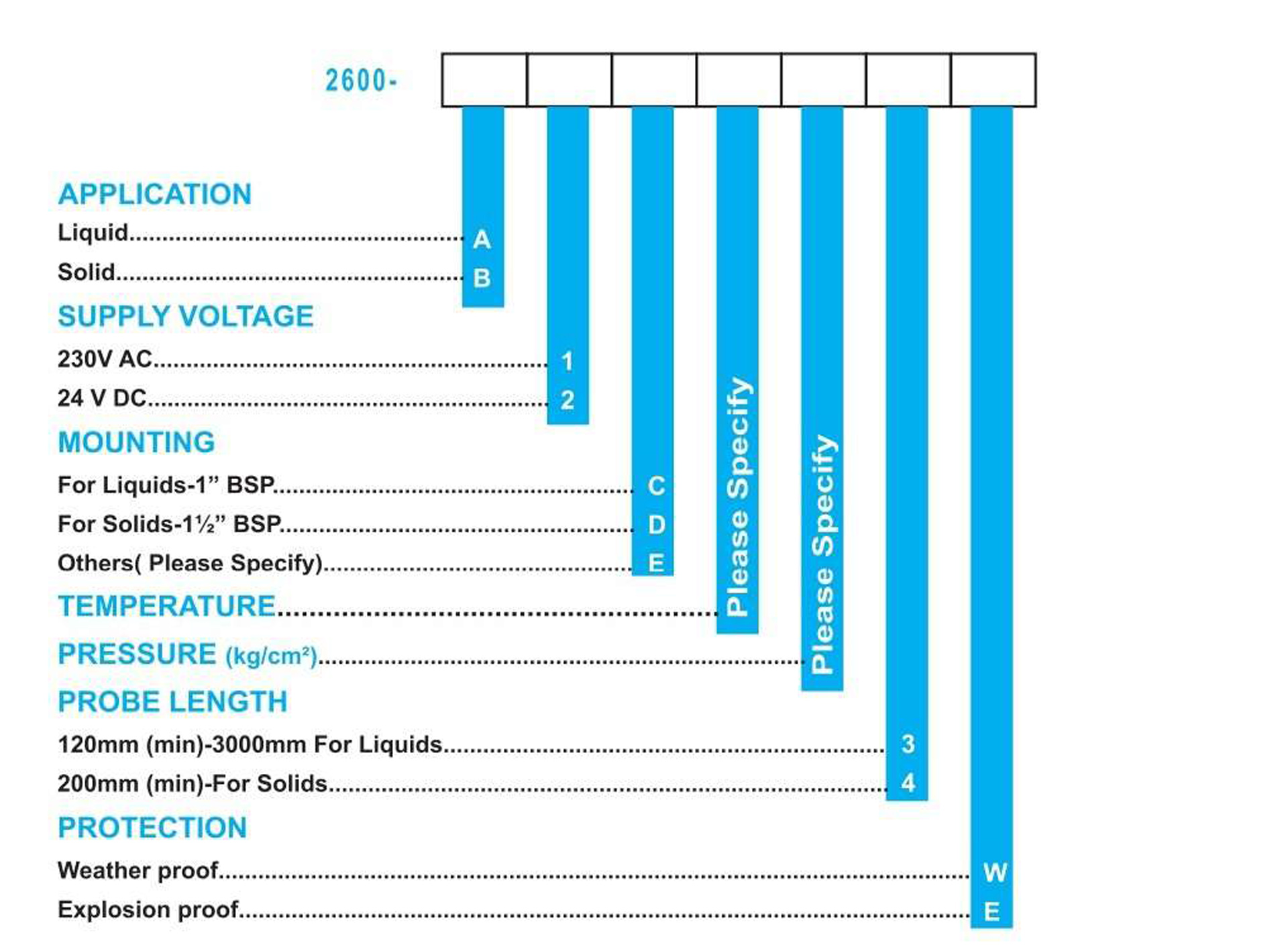

Vibrating Fork Level Switch

Salient Features :

- Fast and Easy Installation

No Calibration. - No effect of electrical properties of the Service material

High Reliability. - Suitable for highly dusty environment.

- Suitable for grain size up to 20 mm.

- Field selectable operation logic.

Can be configured either for High or Low-Level point switching.

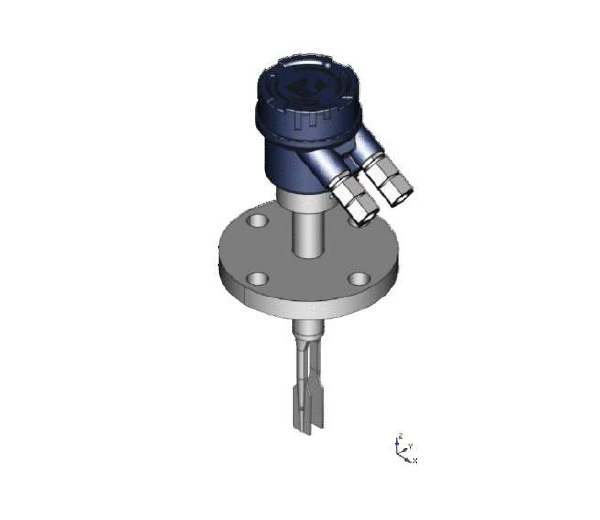

Measuring System

The complete system consists of:

The sensing probe of Vibrating Fork and The Electronic Switching unit.

Function :

The electronically stimulated fork vibrates at its mechanically resonance frequency of about 125Hz/400 Hz when the fork is free of the service material. The resonance is caused by the piezoelectric crystals. One of the piezo crystals produces a small voltage which is transmitted to the switching amplifier. If the fork is covered by the bulk material, a damping effect is produced and the piezo crystal does not produce the voltage and the amplifier will switch and a corresponding signal output is actuated. The vibration of the fork has self-cleaning properties.

The light deposit on the container wall does not affect the operation of the Instrument

Technical Specifications

Switching Unit |

|

|---|---|

| Housing | Aluminium, Integral with the probe/suitable for back panel mounting. |

| Cable Entry | 12-%" NPT |

| Ambient temperature | 0o C ti +60o C |

| Power consumption | 2 VA |

| Main Voltage | 230/110 V AC(+/-15%), 50 Hz OR 24 V dc |

| Output | 2 sets of potential free contacts rated at 5 amps, 230 V AC for non-indctive loads. |

| Switching delay | Continously adjustable 2 to 20 Sec (Probe Free of material or probe covered with material). |

| Safety operation | Field selected switch for Minimum or Maxmimum. (FSL/FSH) switching points. |

| Switch status display | Green LED shows Normal Red LED shows alarm |

| Fork (SENSING PROBE) | |

| Mounting | Screwed – 1"BSP or Flanged |

| Sensor | Fork, Stainless steel |

| Lenght | 120 mm (standard) upto 3000mm (for Liquids) 200mm (standard) upto 3000mm (for Solids) |

| Extension | Pipe Operating Temp in |

| Vessel | 150 deg for the integral switching unit. |