TOC Analyzer

Features of Online TOC Analyzers

Unique, Patented Two Zone Furnace Design

Having two temperature zones assure complete combustion of carbon and nitrogen containing compounds while saving the catalyst life. This is based on the unique patented two-zone furnace design. Reactor design eliminates direct physical contact of the catalyst with the sample, reducing sulphur and halogen poisoning, thereby increasing catalyst service life.

Simultaneous Nitrogen Analysis Is An Option

High temperature catalytic oxidation (HTCO) technology and the in-house developed catalyst allow simultaneous measurement of TC and TNb parameters. The same catalyst serves for combustion of compounds containing carbon and nitrogen.

Ease Of Maintenance

Design of TRL-onlineTOC Analyzer simplifies maintenance. Software generates warning messages for routine maintenance needs allowing the operator to recognize, remotely and take action in time. Maintenance and adjustment requirements are collected in a panel for easy access to each component.

Low Cost Of Operation As Well As Very Low Maintenance Needs

Long catalyst service life as well as extended life of consumable items allow maintenance free 80 days operation, based on hourly monitoring.

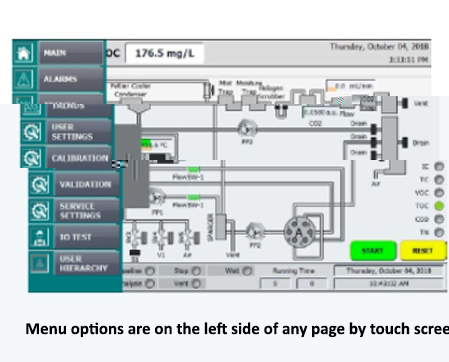

Operator Friendly Software Functions

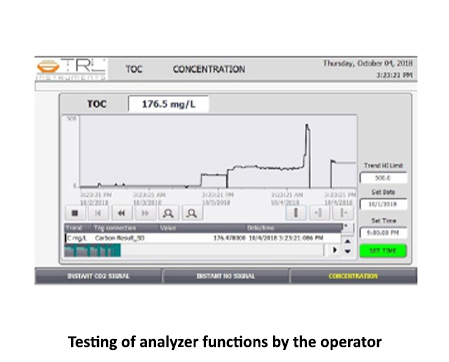

Maintenance chief and technicians can be listed in hierarchy of users and be classified in distribution of authorities. All events are logged and permanently saved. All settable parameters are under the control of the chief and any change is logged, in case. Graphical display of trend is easy to generate on the screen.

Specifications Of TRL-onlineTOC Analyzers

The monitor is designed for continuous operation

Measured parameters: TC or TOC, by operator’s selection; IC and TN are optional additions

Instrument has dual zone high temperature combustion technology and the higher temperature zone is adjustable between 6001000°C

Range is set from 0-5mg/L to 0-1,000mg/ L TOC, operator adjustable. 1000mgTOC/L is achieved without dilution of the sample

Limit of Detection is 0.1mg

Measuring method: High Temperature Catalytic Oxidation (HTCO); TOC is analyzed by direct NPOC measurement, IC removal is achieved by air sparging and acidification

Sensor for carbon analysis is nondispersive infrared detector (NDIR)

Analysis cycle time depends on number of wash cycles, however it is arranged by the operator; nominally between 5 to 20 minutes

Samples at 1 to 2 bar-absolute are introduced without problem, by getting use of internal sampling pump

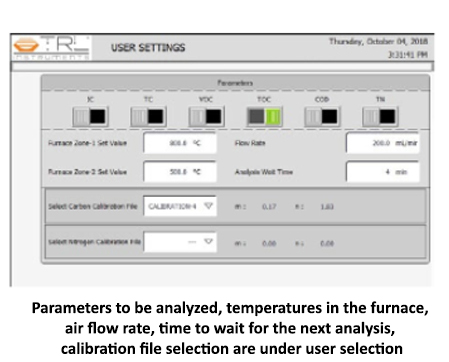

Air flow rate is operator adjustable and nominally about 200mL/min,

Sample temperature of 5°C to 50°C is affordable

Fluid flow for accurate and repeatable injection is achieved through 3 peristaltic pumps plus a 6-port solenoid driven valve

Waste liquid disposal is achieved automatically by peristaltic pump

Ambient temperature of between 5°C and 40°C is good for proper operation

Waste liquid disposal is achieved automatically by peristaltic pump

Communication and available digital outputs: via RS232; date and time, up to 3 measured parameters and error messages; profibus, modbus and ethernet options are available as adders

0-10 VDC and 4-20 mA analog output options are available for future upgrade

2 dry contact alarm limits are set by user

Data storage and data presentation: up to 9999 recent results should be saved and stored, on the basis of “first in first out” method; graphical trend presentation is available on the display and initiated by the operator

Following software functions are available:

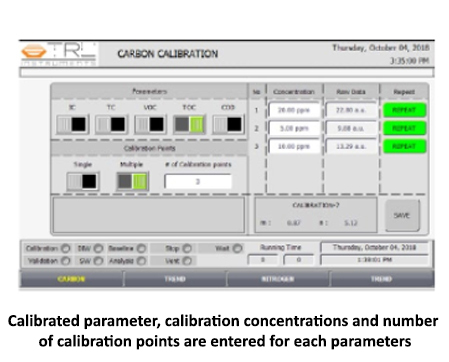

System diagnostics, data storage, optional single or multipoint calibration file storage; single validation cycle;

Design of an analytical cycles as to include as many DI wash and sample wash runs as required; maintenance cycle management and warning of replacement parts based on run cycles;

Continuous control of sample, acid and DI water flows, liquid leakage, furnace

Temperature, air flow rate; air leakage;

Auto-stand-by in case of: emptied acid bottle, sample-acid-DI water leakage, air leakage, furnace temperature failure;

Graphical presentation of trend between settable date and time

System diagnostics, data storage, optional single or multipoint calibration file storage; single validation cycle;

System diagnostics, data storage, optional single or multipoint calibration file storage; single validation cycle;

Power requirement is 230 VAC 50/60 Hz; 1200VA

Carrier Gas: hydrocarbon and CO2 free air at 2-6 bar

Compliance with standard methods: 5310B, EPA 415.1, ISO 8245:1999, DIN1484:1997

The enclosure is NEMA 4 / IP54 compliant and either wall mount or floor standing use is possible

Dimensions (HWD): 138x70x36cm, including wall mount and hanging attachments

Weight: 90 kg

A start up kit is included in the standard pack, for immediate commissioning to operate the instrument at site, for limited number of runs, however a consumables kit is recommended for a year of smooth operation

Shipment is via airfreight. The equipment is packed in a wooden cradle

Lifelong remote support is available

Optional TN Parameter

Accuracy: ± 5 % of range

Limit of Detection: 20ugC/L

Measuring method: HTCO,

TN should be analyzed by NO detection

Sensor for nitrogen analysis is chemiluminescence detector

Ozone generator should be built in the analyzer

Optional IC Parameter

Range: up to 0-2,000mg/L IC, without dilution, operator adjusted

Accuracy: ± 5 % of range at ranges less than 1000mg/L; ± 2 % of reading at ranges over 1000mg/L

Limit of Detection: 0.25ugC/L

Measuring method: by air sparging and acidification

Detection of CO2 by NDIR detector

Optional Higher Range

For very polluted samples up to 0-50,000mg/L TOC, operator settable, achieved by dilution with DI water

Optional TOC Quality Air Generator

Integrated into the system

Should provide quality of air to achieve the given specifications

1 set of spare sorbents for maintenance and refilling

Optional 6 Port Multi Sampling Apparatus

6 sample lines can be connected

All functions are controlled through the software of the main system

Sequence of the sample lines is adjustable

Washing the collection cup by the sample is achieved

Discharge is achieved by peristaltic pumps

Inlet pressure of the sample lines should not exceed 2 bars absolute

Optional analog output-mA

4-20mA analog output for the measured parameters

up to 3 parameters

Optional analog output-VDC

0-10VDC for the measured parameters

Up to 3 parameters

Communication options

Profibus

Modbus RS485

Ethernet

Web monitoring

Optional Consumables Kit

Recommended for one year of operation; includes: 20 gr/pk of catalyst; pk of glass wool; pk of quartz wool, pk of o-rings, pk of moisture trap filling, pk of halogen trap packing, peristaltic tubes

Optional and Spares Parts

Followings are recommended to be kept in stock to assure minimum down time in case of failure of parts:

3 ea trap tubes

1 ea peristaltic pump

1 ea solenoid valve

1 ea filter on CO2 detector

1 ea gas flow meter

3 ea GL14 cap with PTFE quoted septa

We

- Develop

- Design

- manufacture

Processes and equipment, for

- Research

- Production

- Analysis

In the field of

reaction engineering, sorption studies and catalysis research environmental monitoring bioprocesses

To help

development of future energy resources and processes

protection of environmental

development of new materials

scientific development