Orifice Plates

Orifice Plates

- Its cost is low

- It can be used in a wide range of pipe sizes

- It is well-known and has predictable characteristics

- It is available in many materials

Introduction of flow measurement

Measurement of flow rate and quantity is the oldest of all measurements of process varlables in the field of instrumentation. It is made for determining the proportions and the amount of material flowing in or out of process. For the purpose of cost accounting, such measurement is often required to be made for steam, water and gas services. Without flow measurements, plant material balancing, quality control and even the operation of any continuous process would be almost impossible.

General Description

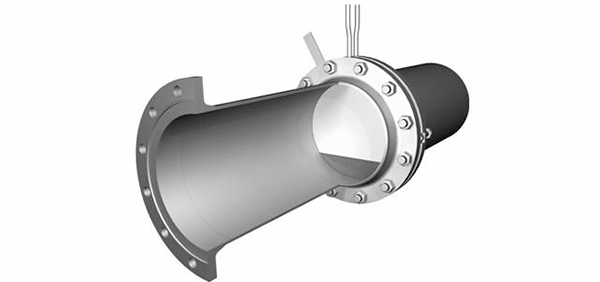

Orifice plates are designed as per BS EN ISO 5187. Orifice plate can be supplies complete with ANSI B16.36 orifice flanges. Orifice plates are the simplest and cheapest form of primary elements and are use more frequently than all other types. An orifice plate is inserted in the line and the differential pressure across it is measured. There are five types of orifice plates which are listed below;

- Concentric orifice plate

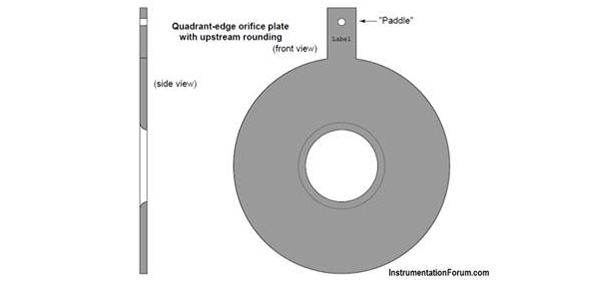

- Quadrant edge orifice plate

- Eccentric orifice plate

- Restriction orifice plate

- Segmental orifice plate

Standard material grades include

- Stainless steel 304/316

- Hastalloy C276

- Super duplex stainless steel

- Inconel 625/825

- Stainless steel 304

- Duplex stainless steel

- Manel 400

Concentric Square Edge Orifice Plate

It is mostly widely used. These plates have a sharp, square edged hole bored in a flat thin plate with or without bevel at the outlet depending on size & usage. It has a circular hole (orifice) in the middle, and is installed in the pipe line with hole concentric to the pipe.

Eccentric Orifice Plate

It is similar to the concentric plate except for the offset hole which is bored tangential to circle, concentric with the pipe and of a diameter equal to 98% of that of the pipe. Location of the bore prevents damming of solid materials of foreign particles and makes it useful for measuring fluids containing solids, oils containing water and wet stream. The eccentric orifice plate is used where liquid fluid contains a relatively high percentage of dissolved gasses, and installed with the bore tangential to upper surface of the pipe when the flowing material is liquid and tangential to the lower surface of the pipe when the fluid is a gas.

Segmental Orifice Plate

This orifice plate is used for the same type of services as the eccentric orifice plate. It has a hole which is a segment of circle, the diameter of which is customarily 98% of the pipe diameter.

Quadrant Edge Orifice Plate

This type of orifice plate is used for flows such as heavy crudes, syrups and slurries, and viscous flows. It is constructed in such a way that the edge is rounded to form a quarter-circle. The plate has a concentric opening with a rounded upstream edge rather than the sharp, square edge normally used.

Restriction Orifice Plate

These plates are used to restrict flow or reduce pressure.

RTJ Oriface Plate

These plates are either made out of single plece or screwed “O" ring joint holder. These are used with WNRTJ flanges for high pressure application.

Multistage Restriction Orifice Plate

These assembles have several orifice plates welded or assembled into one assembly for controlled stage wise pressure drop.