Online Silica Analyzer

Online Silica Analyzer

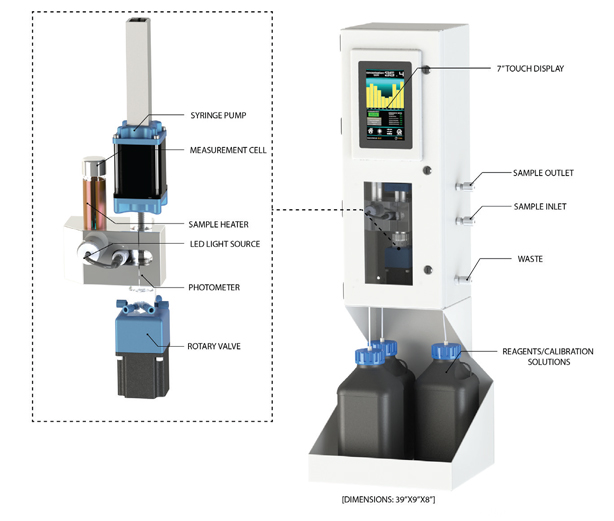

RS1 Colorimetric Analyzer

Introduction

The RS1 Colorimetric Analyzer is designed to automate time-consuming ASTM laboratory based tests in a process setting while producing accurate concentration measurements for many water quality applications. Designed for ease-of-use, simply connect the sample inlet and outlet, reagent, and waste lines and power up the analyzer. Information and customization options are easily accessible via the 7” intuitive touch screen display and user-friendly software. Users will benefit from a higher volume of testing and faster turnaround time while increasing precision, reproducibility, and throughput. The RS1 also reduces human error and enables laboratory personnel to be more productive by focusing less on repetitive tasks. Compared to traditional manual sampling, the RS1 provides operators with a real-time indication of actual process conditions.

Performance profile

- Aluminum

- Ammonia

- Free Chlorine

- Chromium

- Copper

- Cyanide

- Hardness

- Hydrazine

- Iron

- Manganese

- Nickel

- Nitrite

- Phenol

- Phosphate

- Silica

- Zinc

Features

- The RS1 performs fully automated colorimetric measurements in a process setting utilizing up to three reagents.

- Programmable automatic calibration with self-referencing feature.

- Programmable cleaning cycle and long life LED minimizes required maintenance.

- 7” intuitive touch screen display with easy-to-use software allows users to calibrate and view data.

- Dual compartment enclosure ensures complete separation between electronics, sample, and reagents.

- Standard data outputs include MODBUS, 4-20mA, and USB to CST Software.

Theory of Operation

The RS1 is designed to perform fully automated colorimetric measurements and deliver the product of the chemical reaction to an analysis cell in a process setting. The system first retrieves a known volume of sample from a stream and mixes it with up to three reagents in succession. After each reagent addition, a mixing cycle is performed followed by a variable reaction delay. Once the reagent addition process is complete, the final solution is transported to a heated measurement cell where the compound of interest can be determined via an absorbance measurement. The RS1 is designed to be mounted near to the pipeline containing the sample of interest which is retrieved from the pipeline via a fast loop.

Technical Specifications

| General | |

|---|---|

| Measurement Principle | Absorbance |

| Repeatability | Application Dependent |

| Light Source | LED |

| Detector | Silicon Photodiode |

| Inlet/Outlet Pressure | 5 psi maximum |

| Minimum Flow Rate | 100-500 ml/min |

| Calibration | Automatic 2-point calibration; calibration maintained by programmable self-referencing feature |

| Response Time | Application dependent |

| Power Requirement | 24VDC nominal (12-48VDC), 8.5 watts max |

| Dimensions of Analyzer | 39” H x 9” W x 8” L |

| Process Temperature | 147°C |

| Operating Temperature | 5°C to 55°C |

| Storage Temperature | -20°C to 50°C |

| Outputs | 4-20mA, RS-485 (MODBUS), or USB |

| Alarms | Contact closure (60VDC, 0.75 A max) |

| Display | 7” capacitive LCD |

| Detection Range (other ranges available upon request) | Test Method | |

|---|---|---|

| Aluminum | 0 – 1.5 mg/L | ASTM D857 |

| Ammonia | 0 – 3 mg/L | ASTM D1426 |

| Free Chlorine | 0 – 10 mg/L | ISO 7393-2 |

| Chromium | 0 – 1 mg/L | ASTM D1687 – 17 |

| Copper | 0 – 5 mg/L | ASTM D1688 |

| Hardness | 0 – 1 mg/L | ASTM D511 |

| Hydrazine | 0 – 1 mg/L | ASTM D1385 – 01 |

| Iron | 0 – 1 mg/L | ASTM D1068 |

| Manganese | 0 – 100 μg/L | ASTM D858 |

| Nickel | 0 – 3 mg/L | ASTM D1886 |

| Phosphate | 0 – 3 mg/L; 0 – 50 mg/L | EPA 365.3 |

| Silica | 0 – 1 mg/L | ASTM D859 – 16 |

| Zinc | 0 – 2 mg/L | ASTM D1886 |