Oil In Water Analyzers

Oil in Water Analyzers

AUTOMATED EXTRACTION SYSTEM (AES) – OIL IN WATER

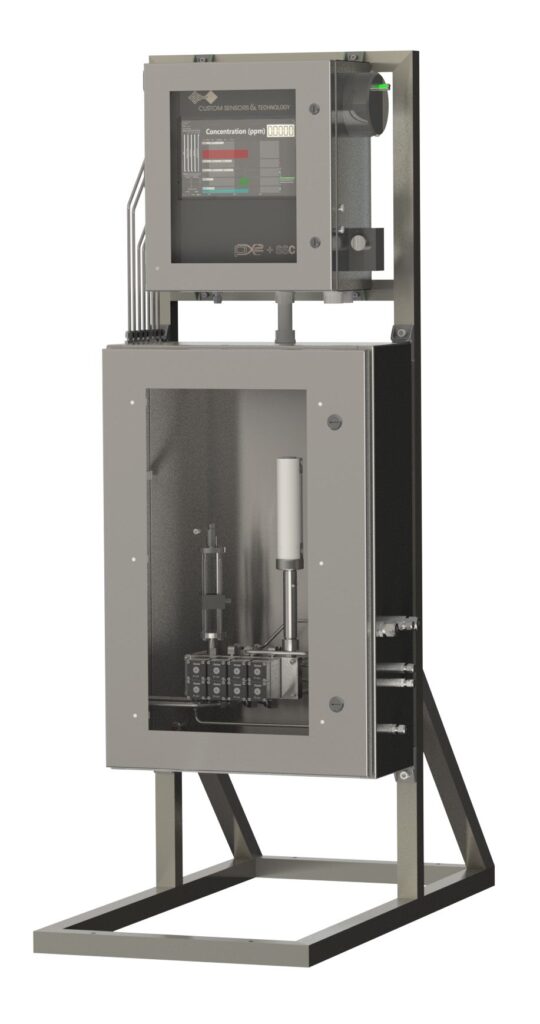

The Automated Extraction System (AES) combines the PX2 Photometer with a programmable sampling system capable of performing fully automated liquid-liquid extractions and delivering the extract to an analysis cell.

First, the AES retrieves a known volume of sample from a process stream via fast loop and adds a known volume of solvent. Next, it mixes the sample and solvent phases to create an emulsion, which allows the solute to transfer to the solvent phase. Finally, the AES instrument determines the concentration of the solute by means a fluorescence measurement made in the analysis chamber.

The AES contains all of the hardware to perform the mechanical functions of the extraction, and is designed to be mounted near the process line at which the measurement will be performed.

The Auto-Tune feature takes the guesswork out of selecting the optimal measurement settings, and the Auto-Calibrate function only requires the user to prepare one standard.

Introduction

The presence and concentration of oil hydrocarbons in domestic and industrial wastewater is highly concerning to the public because of its harmful effect and impact on aquatic life. Regulations and standards have been established that require strict monitoring of oil hydrocarbons before they can be released into the environment. Fortunately, CST’s Automated Extraction System (AES) provides users with a side stream Oil in Water analyzer that utilizes fluorescence to provide accurate measurements of oil concentrations in water.

The AES is capable of performing fully automated liquid-liquid extractions which are critical to eliminating background interferences in the sample. The AES produces reliable real-time data that enables operators to take accurate discharge measurements and to improve efficiency of separation, thus enabling cost

reductions.

Features

- Accurately measures the concentration of oil in water while producing results in real-time.

- Utilizes liquid-liquid extraction to eliminate background intereferences in the sample.

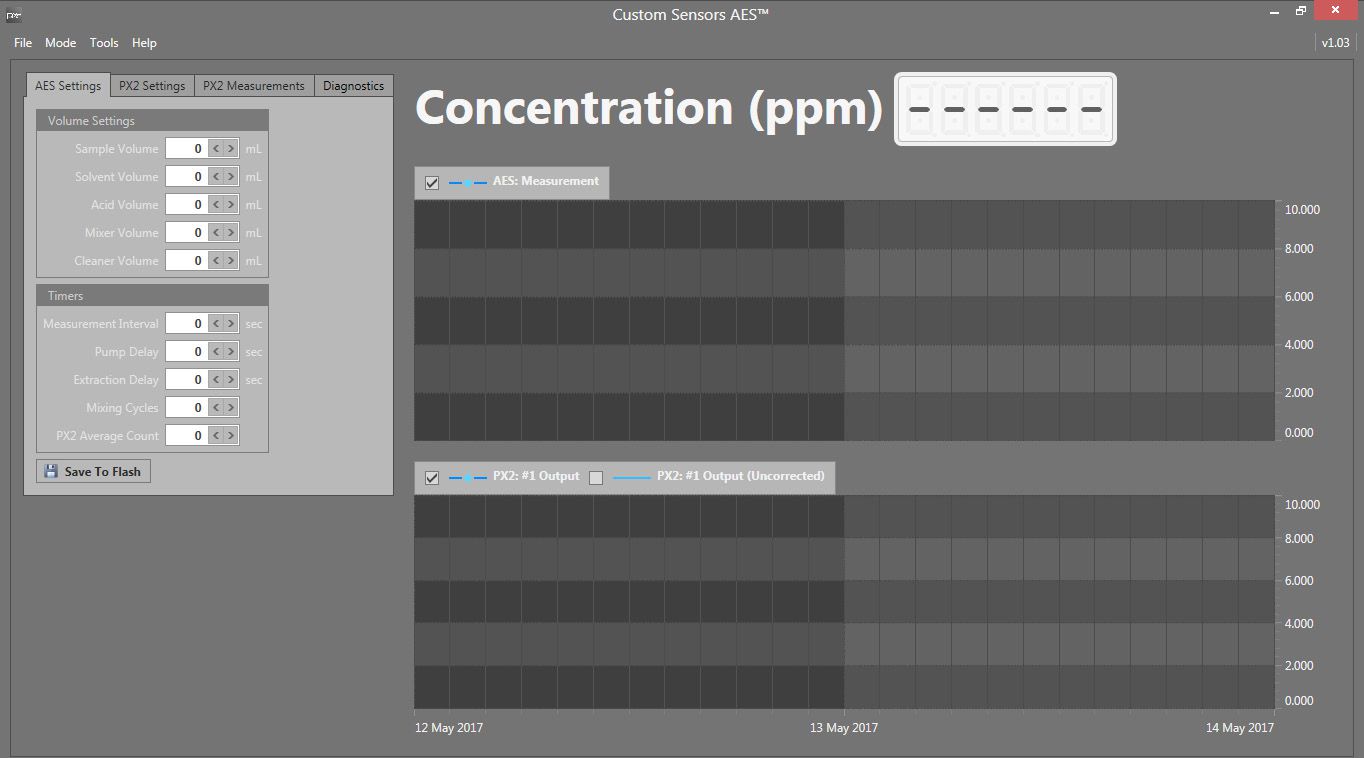

- The AES Control Panel App allows the user to adjust the unit’s measurement, output, and logging settings. It also allows the user to view historical data, export data to Excel as a .csv, and save or restore past measurement methods.

- The Auto-Tune feature automatically optimizes the measurement setting, while Auto-Cal determines calibration points using user-provided standards.

- Standard data outputs include MODBUS, 4-20mA, and USB to CST Software.

- Low cost of ownership with no routine maintenance.

AES - Overview

The AES automatically performs a liquid-liquid extraction in a process setting which is essential in making a precise fluorescence measurement. Liquid-liquid extraction is a method to separate compounds, based on their relative solubilities in two different immiscible liquids.

AES - Operation

First, the AES retrieves a known volume of sample from a process stream via fast loop and adds a known volume of solvent. Next, it mixes the sample and solvent phases to create an emulsion, which allows the solute to transfer to the solvent phase. Finally, the AES instrument determines the concentration of the solute by means of a fluorescence measurement made in the analysis chamber.

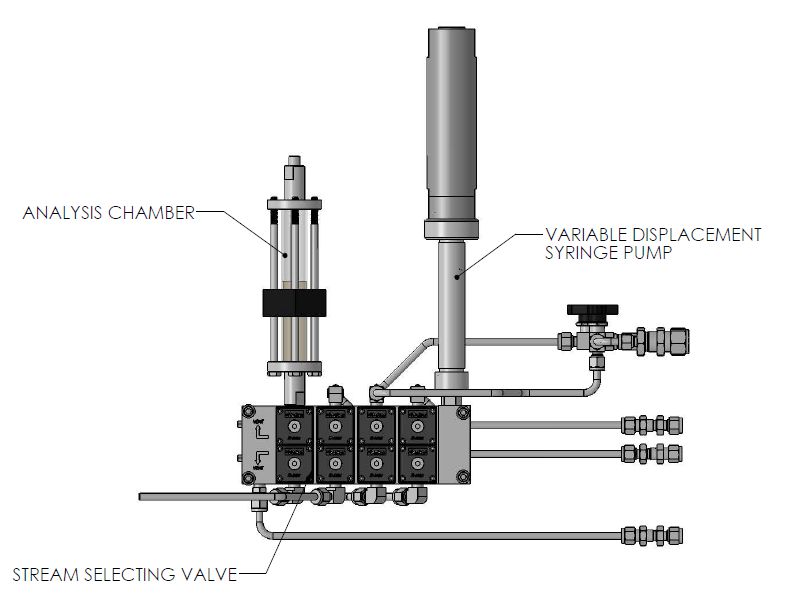

The variable displacement syringe pump meters both sample and solvent volumes and propels all fluids through the system. Sample and solvent ratios may be dynamically calibrated to suit the demands of each unique installation.

Furthermore, the analysis chamber facilitates the extraction and is located in parallel to the syringe pump. The fluids alternate between the analysis chamber and syringe pump to provide the mixing action. Fluid is passed through the entire stream switching valve so that all fluids within the system are incorporated during the extraction process. Fluid is continually exchanged between the analysis chamber and syringe pump until the extraction process is complete. Once complete, the AES makes the fluorescence measurement and displays the concentration.

Theory of Operation - Fluorescence

The AES utilizes fluorescence to accurately measure oil in water concentrations. Fluorescence occurs when a molecule absorbs light energy at one wavelength and re-emits light at another, typically longer, wavelength. The wavelength where the maximum absorption occurs is called the excitation wavelength, and the wavelength where the maximum emission occurs is called the emission wavelength. The AES uses optical filters to provide specific excitation/emission wavelength ranges chosen to coincide with oil fluorescence.

Fluorescence spectroscopy can be used to measure the concentration of a compound because the fluorescence intensity is linearly proportional to the concentration of the fluorescent molecule. Only molecules that fluoresce can be detected by this method, however, the sensitivity and specificity of fluorescence measurements leads to more precise and accurate readings than comparable absorbance measuring methods.

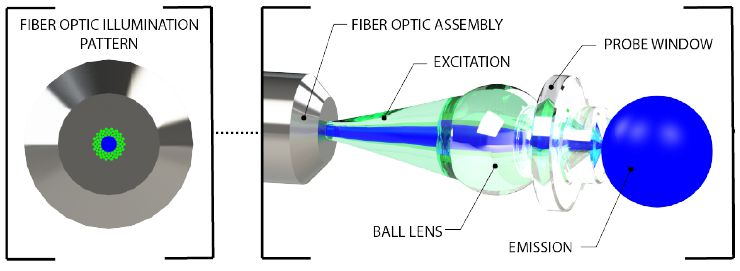

The Front Surface Fluorescence Probe is the key component of making a measurement with the AES. The light source within the AES provides excitation energy to the probe tip via a fiber optic cable. The ball lens, located at the sensing surface of the probe, focuses this energy through the sapphire probe window. The energy is then absorbed by the oil which creates emission energy. This emission energy is transmitted back to the AES by another fiber optic cable and is directed to the measure detector where the concentration signal is detected. The Front Surface Fluorescence Probe is less susceptible to the inner-filter effect and to bubbles or suspended solids because of it’s front surface probe design.

PRODUCT SPECIFICATIONS

Measurement

- Method: Fluorescence via liquid-liquid extraction

- Range: 0-100 ppm to 0-45,000 ppm (configurable)

- Accuracy: ± 1% of full scale or better

- Repeatability: ± 0.5% of full scale or better

Communication

- Output: on-board display, isolated 4-20mA, RS-485 (Modbus)

- Alarm: N.O. relay 60 VDC/0.75A max

Operating Conditions

- Ambient Temperature: 41-122F (5-50C)

- Process Temperature: 41-122F (5-50C)

- Process Pressure: 100 PSI max

Utility Requirements

- Power Required: 88-132 VAC/176-264 VAC, 50/60Hz

- Power Consumption: 120W max

- Instrument Air: 100-110 PSI; 1 cfm max

Physical

- Enclosure: 304 Stainless Steel

- Dimensions: 20″ x 10″ x 50″ (50.8 cm x 25.4 cm x 127 cm)

- Weight: 180 lbs. (81.6 kg)