Marine Loading Arms

Marine Loading Arms

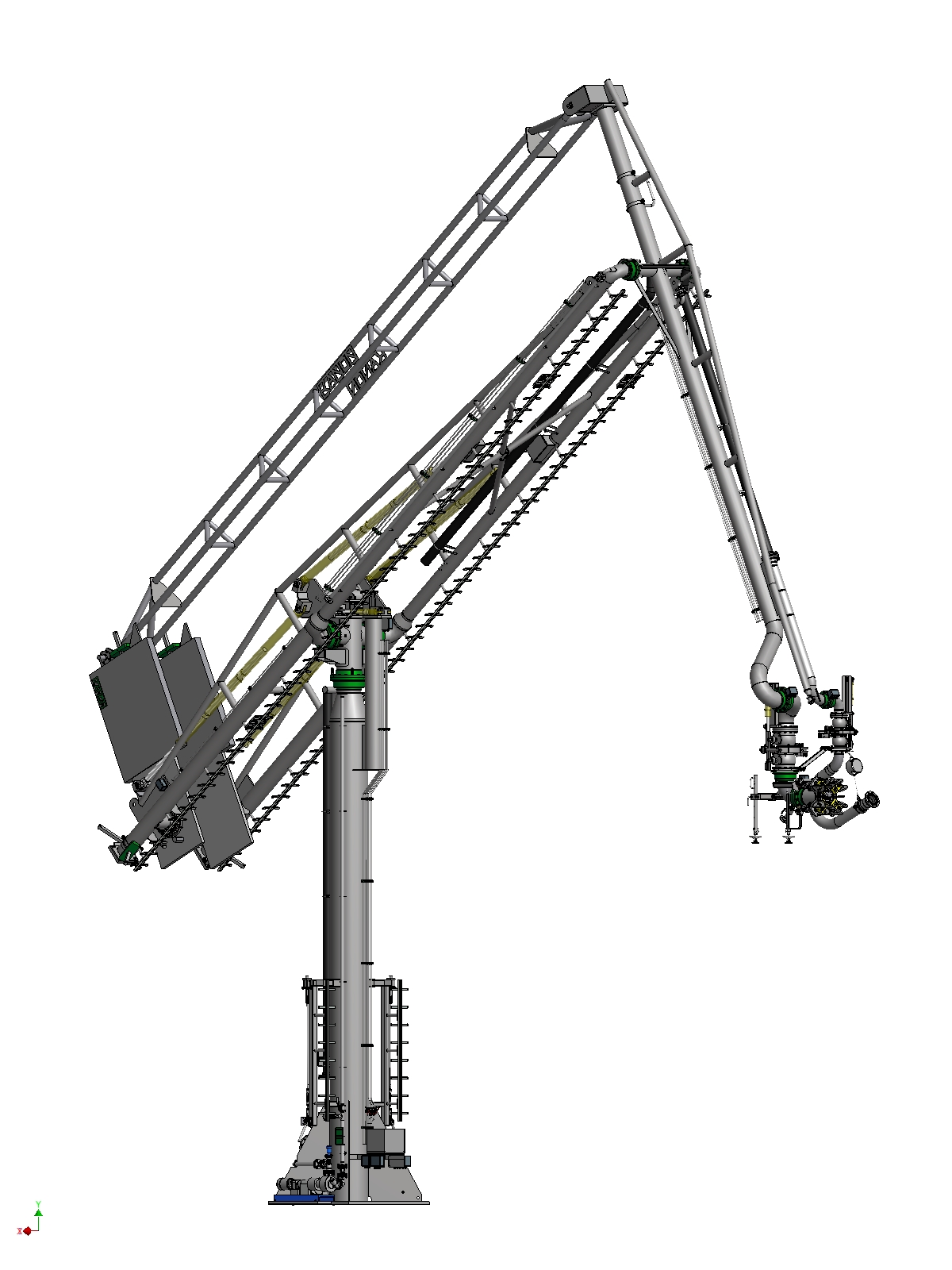

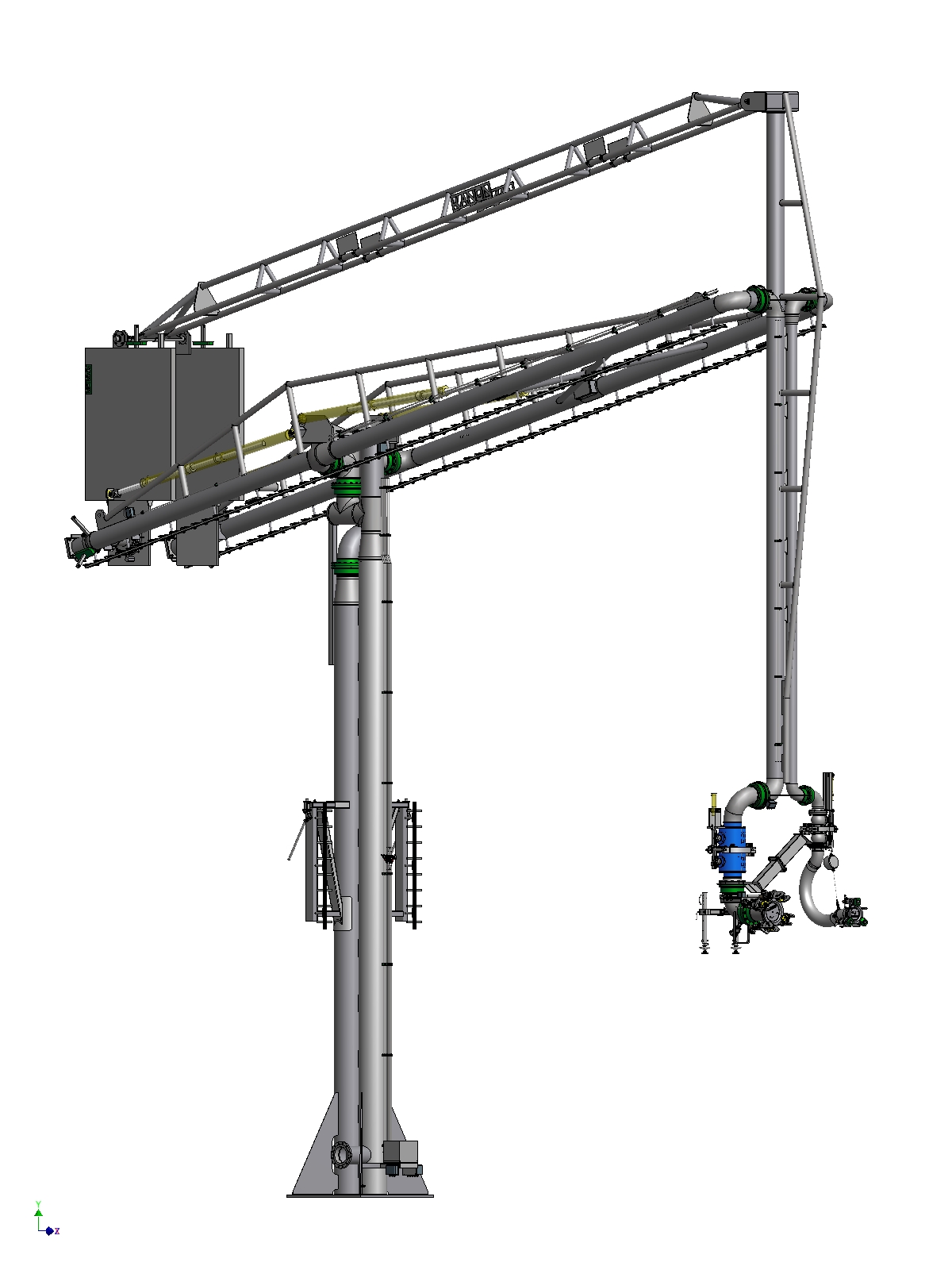

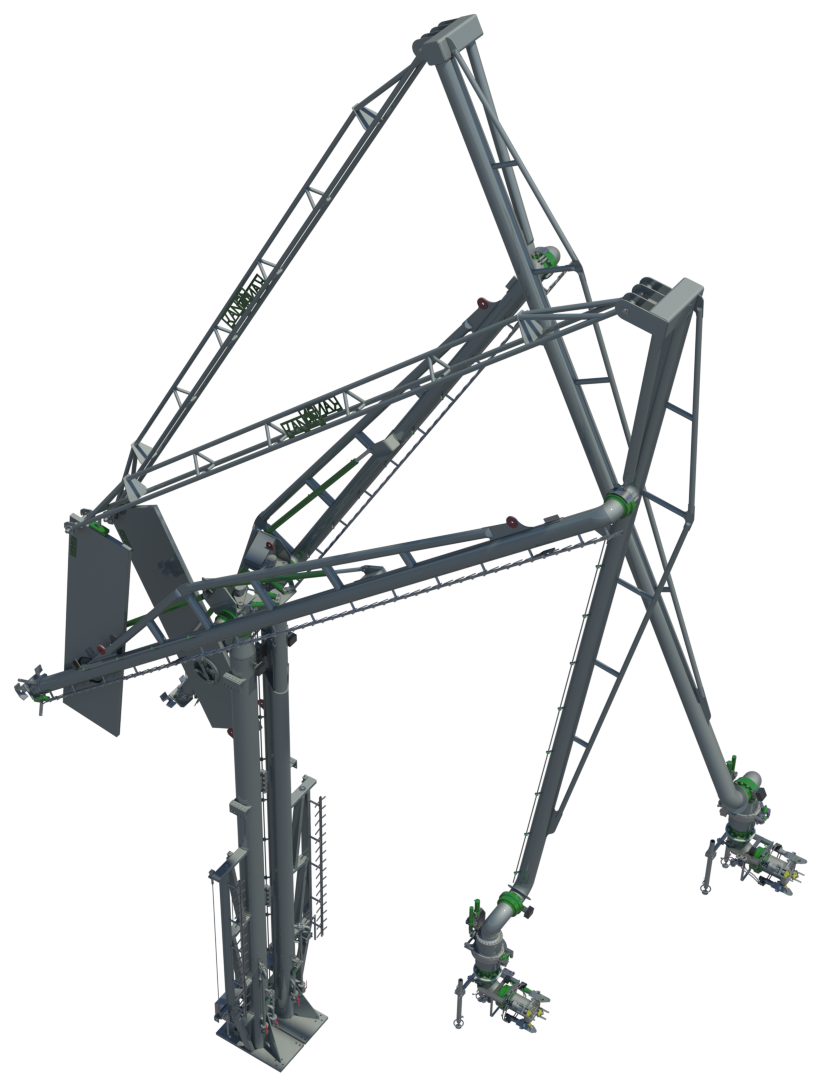

To load or unload a ship, a hose or loading arm is needed to follow the movement of the ship due to the dynamics of changing draft, changing tide, wind and other factors.

A Marine Loading Arm offers a significant improvement over a hose in the transfer of liquids between vessel and shore because It provides an easier and more ergonomic operation, gives longer service life and permits Emergency Release Action without any spillage of product and without any pollution.

Our Marine loading arms are manufactured in line with the latest requirements of OCIMF and demands of major oil companies.KANON Marine loading arms require minimal maintenance and all product seals can be replaced without the need of cranes or dismantling the loading arm itself.

Characteristics

The KANON ERC is part of the KANON range of Emergency Safety Systems (ESS), designed to provide best possible safety in fluid loading/unloading when using Marine Loading Arms.

An ERC provides a fully automatic, safe and spillage free disconnection of the Loading Arm from the ship should the limits of the safe working envelope of the Arm be exceeded.

An ERC is basically designed as two ball valves placed together as close as possible. The flanges between the valves are held together by two shell which are interconnected with a removable connecting rod. After closure of the ball valves and thus release of the ERC one part shuts of the loading arm and the other part remains on the ship and shuts of the ship’s manifold.

The KANON ERC is part of the KANON range of Emergency Safety Systems (ESS), designed to provide best possible safety in fluid loading/unloading when using Marine Loading Arms. The ERC provides a fully automatic, safe and spillage free disconnection of the Loading Arm from the ship should the limits of the safe working envelope of the Arm be exceeded. The ERC features a simple single cylinder design that provides a high level of intrinsic safety, field-proven in many Marine Loading Arm applications. KANON Emergency Safety Systems, and specifically the ERC, are known as ‘workhorses’ in the fluid transfer industry providing powerful performance with little or no maintenance.

Hydraulic QC/DC

KANON has developed an extremely straightforward and robust Hydraulic Quick Connect / Disconnect Coupler with multi-size capability which has proved itself extensively in the field to full satisfaction of terminal operators located from northern territories to (sub) tropical regions. QC/DC Principal: Hydraulic quick couplers offer the possibility of connecting the marine loading arm to the ship’s manifold by means of a single push button, from a remote distance. Moreover there are a number of good reasons to seriously consider using a hydraulic quick coupler:

- Time to connect. Instead of 5-20 minutes for a manual coupler a hydraulic coupler will take only a few seconds.(movie)

- Safety. Nobody needs to work next to the manifolds.

- Emergency. The hydraulic coupler can easily and quickly be disconnected in situations where operators can not close to the manifolds.

- The clamps are completely protected by the guidance’s.

- The clamps will grab the ships flange from a distance of not less than approx. 80mm.

- The clamps will remain positively locked by a self limiting thread in case the hydraulic power fails.

- The clamps can be disconnected manually in case the hydraulic power fails.

- The clamps are all single units and are exactly the same for a wide range of flange diameters (6” ~ 20” and larger) In case of failure of one of the clamp units, there is no need to replace the whole coupler but only the concerning clamp unit needs to be replaced.

- The KANON hydraulic quick coupler with Multi-size capability an be made suitable for two sizes smaller: within only 5 minutes and without any tools, some adapter pieces will transform a 16” coupler into a 12” or even a 10” quick coupler.

- The same coupler can be made suitable for all possible applications.

- Attractive part of the KANON coupler: the best quality against a more than reasonable price.

The greatest thing is the simple, straightforward design. The clamp units are very robust and need basically no maintenance. If any work on the clamp units might be needed, everything including replacement of a clamp unit can easily be done by the terminal’s own maintenance crew instead of calling in for help from OEM service personnel. And because the weight is relatively low, the KANON hydraulic quick coupler with multi-size capability can replace existing hydraulic ones of conventional design already installed on marine loading arms, to increase the ease of connection and almost eliminate further maintenance costs.

Kanon Emergency Release Coupler(E.R.C.)

The KANON ERC is part of the KANON range of Emergency Safety Systems (ESS), designed to provide best possible safety in fluid loading/unloading when using Marine Loading Arms.

An ERC provides a fully automatic, safe and spillage free disconnection of the Loading Arm from the ship should the limits of the safe working envelope of the Arm be exceeded.

An ERC is basically designed as two ball valves placed together as close as possible. The flanges between the valves are held together by two shell which are interconnected with a removable connecting rod. After closure of the ball valves and thus release of the ERC one part shuts of the loading arm and the other part remains on the ship and shuts of the ship’s manifold.

The KANON ERC is part of the KANON range of Emergency Safety Systems (ESS), designed to provide best possible safety in fluid loading/unloading when using Marine Loading Arms. The ERC provides a fully automatic, safe and spillage free disconnection of the Loading Arm from the ship should the limits of the safe working envelope of the Arm be exceeded. The ERC features a simple single cylinder design that provides a high level of intrinsic safety, field-proven in many Marine Loading Arm applications. KANON Emergency Safety Systems, and specifically the ERC, are known as ‘workhorses’ in the fluid transfer industry providing powerful performance with little or no maintenance.