Hydrogen sulfide Analyzer

When reacting with sulfur species in gas the CST H2S scrubber is non-oxidizing and is not exothermic. The CST H2S scrubbers are continuously indicating their usefulness, based on a color change of the scrubber formulationwhen it reacts to H2S and other sulfur species that may be present in your stream. As you begin to run your gas through the scrubber it will turn from green to black indicating that the scrubber is absorbing the sulfur in the gas.

The rate at which the scrubber turns colors is an indication of its consumption. Customers can easily predict how long the scrubber will last based on the consumption rate and when it would be good to send the spent scrubber back to CST for recharging.

Theory of Operation

The PX2+ Photometric Transmitter utilizes Beers Law (the absorbance of light as it passes through a substance) at a specified wavelength to monitor changes in the concentration ofan analyte in process. It sends optical radiation from a source within the instrument out to a flow cell and returns the signal to the instrument via fiber optic cable. The path length of the flow cell can be factory set at 0.1 cm. up to 3 meters to monitor concentration ranges as high as 0-100% or as low as 0-10ppm.

The signal is linearized, and the resulting analog or digital signal can be sent to a PLC or DCS for process control.

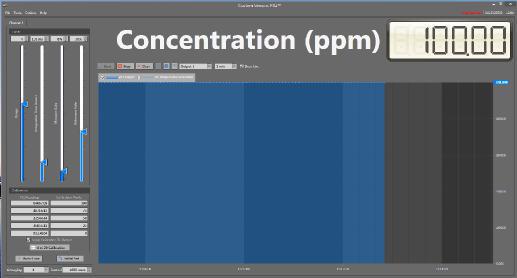

PX2+ Control Panel App

The PX2+ Control Panel App allows the user to adjust the unit’s measurement, output, and logging settings. The Auto-Tune feature automatically optimizes the PX2+’s measurement setting for a particular application, while Auto-Cal determines calibration points using user-provided standards.

The PX2+ Control Panel App also allows the user to view historical data, export data to Excel as a .csv, and save or restore past measurement methods.

H₂S Analyzer Advantages

- Wide Range: monitor 0-100% or as low as 0-10ppm.

- Auto-Tune: fill the flow cell with zero gas and let Auto-Cal determine the optimal settings.

- Pressure/Temp Correction: dedicated outputs for pressure/temp allow for automatic measurement correction.

- Robust: 3000psi max at inlet, regulated down to 500 psi max within the flow cell.

- 1 Consumable: Xe light source typically lasts ~5 years.

- Solid State: no moving parts; gas is brought directly from process and analyzed in flow cell.

- Fiber Optic Sample Interface: only the sealed optics contact the sample; since the electronics are connected to the sample interface via fiber optic cable, the electronics can be installed away from the process.

- Area Specific: various enclosure options include NEMA 4X, C1D1, and C1D2 (ask about others)

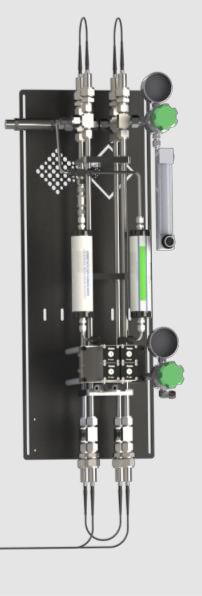

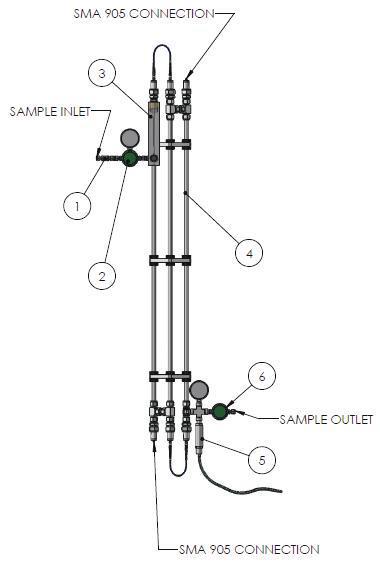

3052 Series H₂S Flow Cell Specifications

ITEM DESCRIPTION

- 7 MICRON PARTICULATE FILTER

- 0-100 PSI PRESSURE REGULATOR

- 0-300 CC/MIN FLOW METER

- FLOW CELL

- 0-100 PSI/ -45-85 C PRESS/ TEMP TRANSMITTER

- 0-100 PSI BACK PRESSURE REGULATOR

- Fiber Optic Connections: SMA-905 to PX2+

- Inlet Pressure: 3000psi max.

- Outlet Pressure: Atmospheric pressure

- Panel Mount: Standard

- Path Length: 0.1cm to 3 meters

- Pressure/Temp Signals: 4-20mA to PX2+

- Wetted Materials: 316 SS, Kalrez, and Sapphire standard

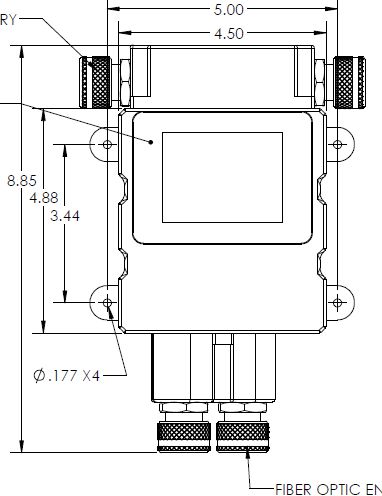

PX2+ Photometric Transmitter Specifications

- Wavelength Range: 185-2600nm

- Precision/Accuracy: 1% of full scale or better

- Light Source: LED, Flash Lamp

- Detector: PMT, Si Photodiode, InGaAs Photodiode

- Display: 3.2″ Capacitive Touch Screen Display

- Alarms: Contact Closure (60 VDC, 0.75 A max.)

- Analog Output: 4-20 mA, isolated

- Analog Loop Resistance: 500 ohms @ 24 VDC

- Digital Output: USB-B, RS-485 (Modbus)

- Power Consumption: 8.5 watts (max.)

- Power Requirements: 24 VDC nominal (12-48 VDC)

- Enclosure Material: Aluminum

- Size: 5” H x 5.8” W x 2.8” D

- Temperature: 5-55 C

- Weight: 3.5 lbs. (1.6kg)