Ban Magnetic Level Indicator

Introduction:

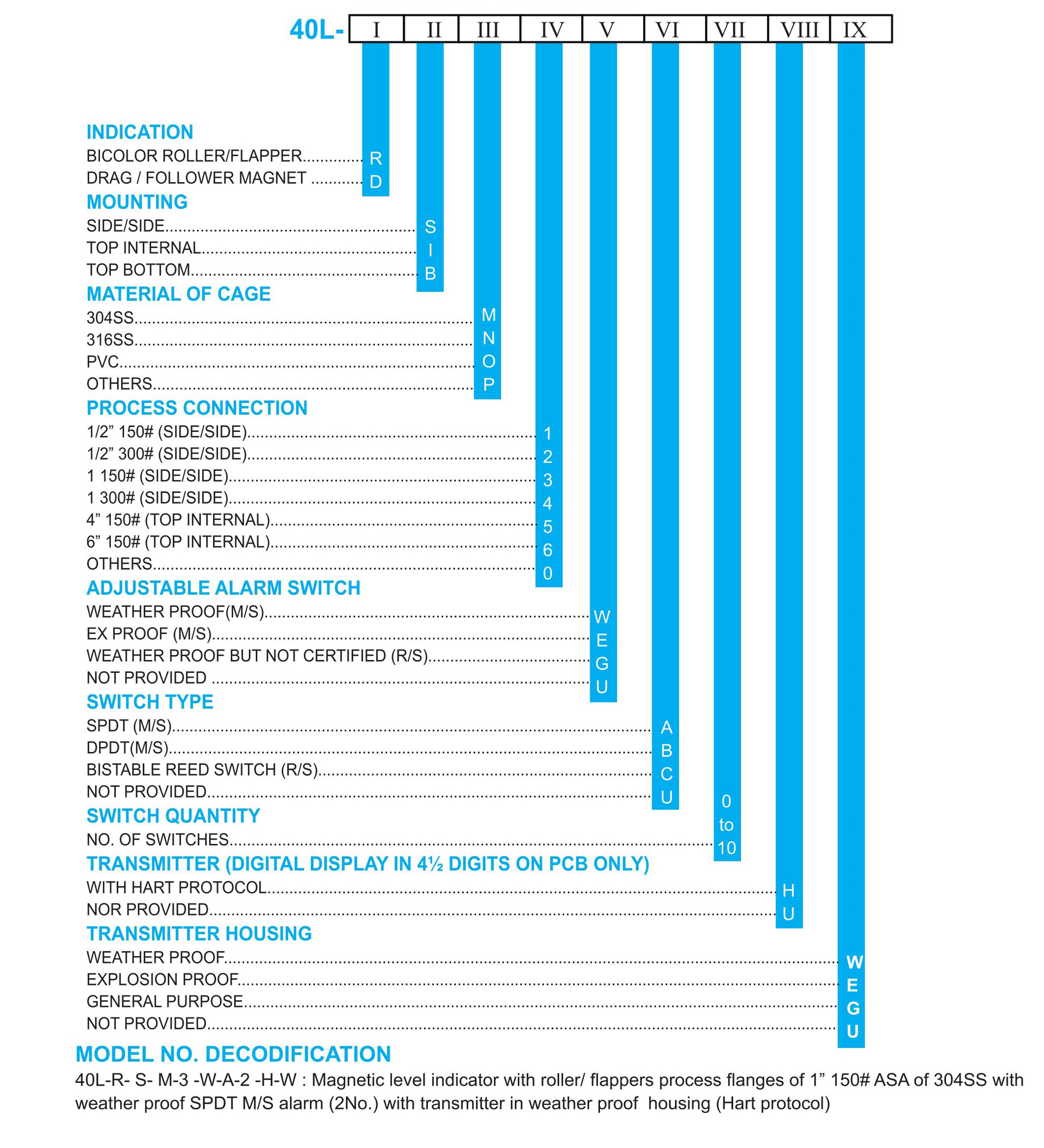

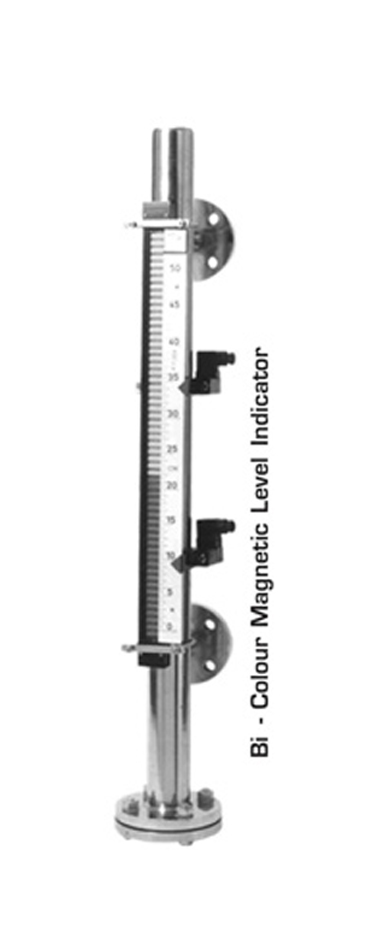

Series 40L Level Indicators are laterally to be flanged to the tank for communication of level of liquids and liquefied gases in open and closed tanks. These can be used when instruments with high resistance to pressure and temperature are required or if sight glasses or similar indicating parts for reasons of safety cannot be used. This measuring system is preferred because there is a safe pressure and fas tight separation between measuring and indicating parts. Magnetic level indicators can be either side mounted or top mounted. These instruments are suitable for a wide range of applications for the chemicals, pharmaceutical industries, petrochemical industries, refineries, oil and fuel tans etc. The float cage is flanged to the tank & the level is indicated through a float which consists of a permanent magnet. The floats are available in various materials like 304SS, 316SS, titanium, PVS etc.

Principle of Operation:

These models consist of Bi-coloured magnetic rollers/flappers equipped with small rod magnets, which are rotated one after another at an angle of 180′ by the directed field of the Permanent magnet inside the float. In addition, Level sensing elements can be fixed directly to the float cage, so that simultaneously liquid level is electrically measured through smart transmitter with output of 4 20mA. It is possible to connect Level indicating Meters and set point Relays at any distance for control and display purpose. The magnetic Level transmitters can also be supplied with HART PROTOCOL. Moreover it is possible to attach bistable Magnetic Switches to the Magnetic Level Indicator in order to get switching at any desired liquid level.

Specifications of Magnetic Level Indicator Without Transmitter

| Float Cage material | 304SS, 316SS, PVC/PP |

| Max. centre to centre distance | 12 meters, (2 meter for PVC/PP) |

| Connecting flanges | According to DIN or ANSI B16,5 |

| Rated Pressure/Temp. | a) 150Kg/cm 21450 C for SS cage b) 10Kg/cm 2 100°C or PVC cage |

| Min. SG | 0.5 (Lower SG on request) |

| Interface Reading | Yes |

| Scale | 304SS, Graduated in ‘mm’ |

| Indicating length | 100% for SS & 75% for PVC/PP |

| Alarm (adjustable) | a) Micro Switch b). Bistable Reed Switch |

| Measuring Accuracy | ± 10mm |

| Roller Misbehaviour | 2 rollers/300mm |

SPECIFICATIONS OF SMART TRANSMITTER (HART Protocol)

| Transmitter Tube | Stainless Steel |

| Max. Transmitter Length | 12 meters |

| Terminal Box | Aluminium |

| Resolution | 20mm standard |

| Supply input | 24V dc |

| Output | 4-20mA for load upto 600 ohms |

| Transmitter Housing | General purpose/ Weather Proof/ Explosion Proof |

Specification of Contact Amarm Switch

| 1) Micro Switch type (M/S) | SPDT/DPDT |

| Switch Enclosure | I) Weather proof IP66 II) EP & WP certified for groups IIA, IIB & IIC |

| Minimum separation | 100 mm |

| Rating | 5A, 230V AC/ 0.5A, 110V dc |

| 2) Reed Switch type (R/S) | Bistable |

| Switch Enclosure | General purpose Housing |

| Minimum Separation | 50 mm |

| Rating | 5A, 230V AC/0.5A, 110V dc |