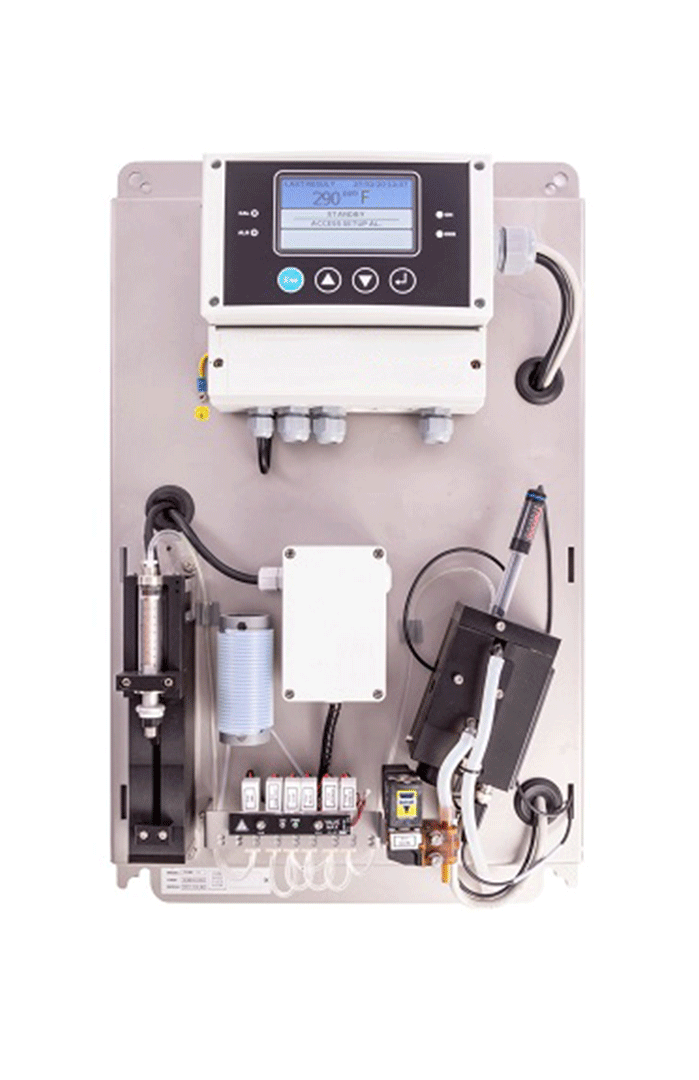

Online Analyzer - Water Quality Parameters

Features

- Developed to determinate the main water quality parameters concentration.

- Powerful in its ability to run different functions and flexible to program easily

according to customer requests. - Reliable. The mechanical elements have been selected due to its strength and

quality to prevent damage. - Low volume of reagents to increase autonomy.

- Low maintenance.

- Economical.

- Adjustable to different kind of samples thanks to self-cleaning system

MODELS

- COLORIMETRIC

Concentration determination after calculating the absorbance and using Beer-Lambert law. - ISE (ION SELECTIVE ELECTRODE)

Ion selective electrode used to determinate the concentration according to Nernst equation. - TITRATION

Colorimetric or ISE titration, depending on the type of measurement

PARAMETERS

COLORIMETRIC

- Aluminium (Al)

- Boron (B)

- Copper (Cu)

- Chromium VI — Chromium Total [Cr(VI)—Cr total]

- Cyanide (CN)

- Cyanuric acid (C3H3N3O3)

- Iron (Fe)

- Manganese (Mn)

- Nickel (Ni)

- Nitrite (NO2—)

- Phenol (C6H6O)

- Phosphate (PO4)

- Silica(SiO2)

- Chlorate (C103—)- Development status

ISE

- Ammonium (NH3 — NH4)

- Chloride (Cl—)

- Chlorine (Cl—)

- Fluoride (F—)

- Nitrate (NO3—)

- Sodium (Na+)

TITRATION

- Alkalinity

- Boron (High range)

- Chlorine (High range)

- Calcium hardness

- Total hardness

PRODUCT SPECIFICATIONS

- CLEANINGS

Scheduled cleanings before and after each analysis with sample, DIW or specific solution - ANALYSIS CORRECTIONS

Temperature correction

Blank correction

LED current correction - DOSE SYSTEM

Syringe driven by step by step motor

Accuracy: 0.015 ml - FLUID SYSTEM

Loop to protect the syringe

Valves made of Kalrez

High resistance tubing (Tygon 2375)

Complete system without fittings - REACTION VESSEL

Low volume glass vessel (17 ml)

Automatic system to prevent overflow

Special design to make drain easier. - SAMPLE CAPTURE – FAST LOOP

Inlet: 6 mm tub.

Outlet 8 mm iub_

Fast loop inlet.

Sample level detector.

Anti-overflow system.

Manual valve to drain while manual cleaning. - ENVIRONMENTAL CONDITIONS

0°C a 45°C - POWER

Input: AC 100-240V — 50 Hz

Max power: 288 W - SET UP

Steel frame,

IP66 enclosure, - SIZE

Steel frame 65x40x15 cm

IP66 enclosure, 75x55x30 cm - USER INTERFACE

Keypad with 4 keys and 4 indication LEDs - LANGUAGES

English, Spanish - COMMUNICATIONS

4-20 mA signal

RS-485 communication

RS485 MODBUS or PROFIBUS - RELAYS

4 Relays (24V), assigned by user. - DIAGNOSTIC MENU

Self-evaluation of analyzer status. - CALIBRATION

Manual o automatic. - ANALYSIS

Manual o automatic.

FEATURES

- MOUNTING OPTIONS

In wall or rack, for indoor use

In an insulated cabinet: standard IP66 of fiber or polyester - DIMENSIONS

In rack: 65x40x15

In cabinet: 75x50x30 - USER INTERFACE

Keypad with 4 keys and 4 indication leds

Configurable menus in several languages - DISPLAY

Backlit monochrome – 8 lines x20 characters – Color, backlit, graphic and panoramic (optional) - MEMORY

Microprocessor with internal program (firmware) upgradable via miniUSB or MicroSD

Registration of 64 analysis, 16 calibrations and 32 alarms or errors, depending on FIFO file - ELECTRICAL CONNECTIONS

100-240VAC , 200Wmax, 50/60Hz // Optional 24V DC 50Wmax

Fuse protection 5A-250V - COMMUNICATIONS

Two 4-20mA analogical outputs, separately configurable and galvanically isolated

One RS485 two-wire bus output

Optionally, the RS485 can use MOD-BUS or PROFIBUS protocol

Two digital inputs assigned to the detection of lack of sample and reagents

Five assignable digital inputs

Two assignable digital outputs

USB.Loading of I/O programs and data

USD Card data and I/O program - RELAYS

Four relays with three contacts (C, NO and NC), potential

free and assignable per program - CALIBRATION

Scheduled automatic

Automatic On-demand

Reagent blanks

Upto three standards - WASHING

Automatic after each trial

With the sample itself

With wash solution (op) - DISPENSING SYSTEM

Syringe dispensing system

Fast loop sampling system, which allows that the syringe

never touches the samples or the reagents

Solenoid valves with Kalrez seals give a high reliability

Large diameter (1,5mm) in the solenoid valve - REACTOR

Small volume reaction vessel (from 12ml to 17ml)

Drain solenoid valve with a large passage section (3mm) - FLUID SYSTEM

Tubing made of inert material

Teflon tube in the loop

Tygon 2375 tube (reagent resistant)

Solenoid valve union with direct connections and without

coupling - SAMPLE INLET

Fast extemal loop with built-in filter (optional

Inlet: 6/8mm diameter tube

Atmospheric drain: Inlet fitting for 8/10mm diameter hose - ENVIRONMENTAL CONDITIONS

Ambient temperature: 10°C to 50°C

Maximum relative humidity: 95% non-condensing